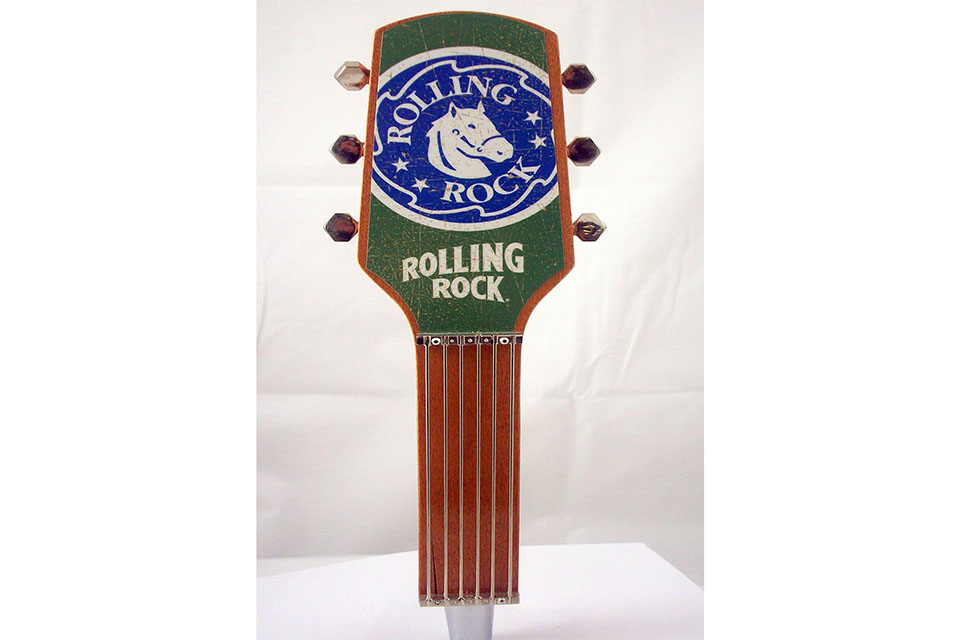

Floor-to-ceiling cabinets run along the walls of a conference room at AJS Tap Handles in Random Lake, and packed behind the glass cabinet doors are at least 1,500 different tap handles, all pieces of art.

The handles – in all sorts of shapes such as dragons, kings, palm trees or guitars – are handcrafted and customized for breweries of all sizes.

The conference room at AJS Tap Handles located in Random Lake holds at least 1,500 tap handles the company has made since it was started by Andy Sanfellipo in 1987. (Andrea Anderson/WPR)

There are the herons made out of urethane for Central Waters Brewing Company in Amherst, all hand painted by the eight to 10 local artists AJS partners with.

Or the more simply shaped handle that doesn’t distract from the eye-catching artwork for Second Salem Brewing Company in Whitewater.

And the classic Leinenkugel’s Oktoberfest canoe that makes you want to yell, “Prost!” and wear your best German attire.

The list goes on, and each is stunning.

Even the ones people may say are more simple, like the handles for MobCraft Beer in Milwaukee, catch your eye – and that’s the point, says Bob Zirngible, sales director of AJS Tap Handles.

“It’s very important,” Zirngible said. “I think it’s the first thing that a customer sees when they come into a bar. And if they’re looking for something different, a tap handle can create that first beer for them because if they see something they like, yeah, they’ll naturally go for it.”

When people think of Wisconsin, one of the first things that comes to mind is the state’s rich brewing history.

But one thing people may not think of when it comes to beer, is the tap handle – the colorful sometimes ornate handle bartenders push or pull to pour that delicious beer.

Workers shape and sand tap handles on the factory floor of AJS Tap Handles in Random Lake on Wednesday, Nov. 7, 2018. The company has been open since 1987 and claims to be the top producer of tap handles in the United States. (Andrea Anderson/WPR)

The business in Random Lake, wedged between Milwaukee and Sheboygan, has been open for 32 years, and it bills itself as the top producer of tap handles in the United States.

“Our mission, our goal is to make the best tap handles for everyone in the brewing industry, whether it’s tap handles made of wood, which we make 100 percent here, or urethane, or metal,” Zirngible said. “We work with a lot of breweries throughout the entire country, and actually world-wide, creating the best tap handles, no matter what materials they’re out of.”

The company was started in 1987 by Andy Sanfelippo and picked up steam throughout the years. Hankscraft Inc., a manufacturer based in Reedsburg, bought the company in 1999.

The company prides itself on working closely with breweries of all sizes, such as massive beer companies like MillerCoors and Budweiser, or smaller breweries like 3 Sheeps down the road in Sheboygan, Capital Brewing in Middleton, or Lagunitas all the way across the country in California.

An AJS Tap Handles employee works in the painting room Wednesday, Nov. 7, 2018 after lining up several Miller Lite handles on rolling carts that need to be painted before heading to the drying room and then the detail room at the facility in Random Lake. (Andrea Anderson/WPR)

“As the craft brewing industry started to take hold almost 10 to 15 years ago, we were there side-by-side and continued to grow with those brands and also continued to do business with the major players, like Miller our next-door neighbor actually, Budweiser, some of the larger brands that we did a lot of handles for,” Zirngible said. “But as the brewing industry continued, we didn’t forget about the small craft brewers. And actually, that’s where a lot more of the fun is involved because they’re more creative.”

The process all begins with a visit or long conversation with the client about what the vision for the handle is and what they want it to represent.

For some larger breweries, the handles aren’t as important as they are for smaller breweries or mid-size breweries where “that handle means everything: that’s their name; that’s their face; that’s their identity,” Zirngible said.

Judi Winker smooths and covers blemishes on the factory floor of AJS Tap Handles on Wednesday, Nov. 7, 2018. The beer can shaped handles are stock handles the company sells to companies. Winker has been with the company for 19 years. (Andrea Anderson/WPR)

The creativity in the handles can be seen when you order, and most of the work starts and stops at the Random Lake facility, where administration, sales, design, factory and shipping work all happen under the same roof.

In a November visit to the factory, a man was in his work zone making urethane molded handles. Outside his room stood racks of previously made handles, some of which took hours of brainstorming, and trial and error, to perfect.

Farther down the factory stood men and women using dies and machines to shape the wood handles and sand the wood. Then workers sand, paint and attach any labels or decals by hand.

On average it takes four to five weeks for a wood handle to be completed. The more ornate the handle, say a figural or a specific shape made from urethane that needs hand painting, takes about eight weeks.

“What I like, too, about our business here is that we’ve got a lot of workers out here, they’re making these by hand,” Zirngible said as he walked the factory floor. “The tap handles are all made by hand, they’re painted by hand, decals are put on them by hand. The only machinery that we’re really using is to shape and create the type of handle that you’re looking for. After that it’s all by hand. They are artisans.”

The company does the majority of its work at its plant in Random Lake, but it does give clients the option to have work done at the company plant in Suzhou, China. But Zirngible said the brewing culture is focused on staying local, so most breweries choose to stay in the U.S.

“Our major competitor makes 100 percent of their handles in China, 100 percent,” he said. “So, if it does come down to price, that’s usually where we will bring China into the game plan. But

we’re seeing more and more of U.S. breweries that want to have their handles made here, and for good reason: their beer is made here, and so our tap handles are made here as well.”

- Finished Miller Lite handles sit in the detail room Wednesday, Nov. 7, 2018 at AJS Tap Handles in Random Lake after workers placed the finishing touches for the large order. (Andrea Anderson/WPR)

- Kathy Yearling sands away blemishes on wood bats on the factory floor of AJS Tap Handles on Wednesday, Nov. 7, 2018. The bats are prototypes for future products. Yearling has been with the company for 22 years. (Andrea Anderson/WPR)

- Jackie Jentges, who has been with AJS Tap Handles for 29-and-a-half years, was attaching decals by hand to SpindleTap Brewery tap handles Wednesday, Nov. 7, 2018. (Andrea Anderson/WPR)

In a room called the detail room, Jackie Jentges was attaching decals by hand to SpindleTap Brewery tap handles.

Jentges has been at the company for about 30 years, nearly as long as its existed.

She has long lost track of how many different styles of handles she, and the company, have done.

“When I started here 29.5 years ago, I thought to myself, ‘OK, it’ll be a cool job for a while. How many tap handles can one person, or one company make?’ Well, here I am now, almost 30 years later, and it’s amazing the number of handles we’ve made,” Jentges said in November. “I’d like to know how many different styles of handles we’ve done over the years.”

And even during her decades of work at the company, Jentges still gets a kick out of going to a bar or restaurant and seeing a tap handle her company designed and her colleagues made.

“When you go to a bar and you walk into a bar and the first thing you do is instinctively look at the tap handles and you sit there and go, ‘We made that, we made that, we made that,’ you know what I mean, and then the bartender looks at you and you’re like, well I work at a place that makes them. It’s fun.”

It’s fun, and it’s a form of art, Zirngible said.

“It’s natural for us to be doing tap handles in the beer capitol of the world, really,” he said. “I mean, the state of Wisconsin, we’re beer brats and cheese … So it’s perfect to have a tap handle company here.”

This story was part of WPR’s High Tolerance series, a look at Wisconsin’s relationship with alcohol.